Our goal with this series of articles is to introduce SAR's departments, spanning from Hammerfest in the north to Stavanger in the south. Throughout our series, we will tell what characterizes the various departments, and how the good cooperation between our departments helps our customers create value from their waste. Here comes article no. 3 in this series! We have now traveled over half the length of the country, all the way south to Kristiansund.

In Kristiansund, SAR is located approx. 10 minutes' drive from the city centre, on the island of Nordlandet. Kristiansund is a city that stretches over 3 islands, located roughly halfway between Ålesund and Trondheim. It has a long history with both marine- and offshore industry, klippfisk and opera. Kristiansund is a central city with many players and suppliers to the offshore industry. Hence, traditionally there has been a focus on recycling and sustainable handling of waste, with SAR as the main player since 2002. Here they receive over 33,000 thousand tonnes annually, distributed across different fractions.

A workplace that stretches both north and south

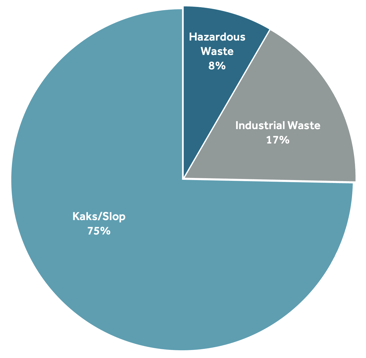

SAR Kristiansund has been established since 2002, when SAR took over the area and operations from Franzefoss recycling. Here they work with the reception, sorting and forwarding of drill cuttings and slop from the oil industry, as well as industrial waste and hazardous waste from offshore, local companies, construction projects and industry. With 19 permanent employees, plus project-based help on site, good collaboration is important. Like many other SAR facilities, it is a relatively small group that is well connected. The department is led by Rune Brattset, who can testify to a motivated team that does a good job and gets along well.

SAR has a general attitude of allowing employees to have varied tasks and allowing them to develop within their field of interest. This has been shown to have a good impact on the working environment.

Kenneth Romfo Nordbø, Operator at Hazardous Waste, sums it up like this:

"The most interesting thing about the job is that it offers so many different tasks. Almost no day is the same, so I rarely get bored. I learn something new almost every day and I find that motivating."

You rarely play just one role at work. When supply boats suddenly come in fully loaded after a long period of stormy weather in the Norwegian Sea, all you can do is get a move on and everyone has to know the workflow. The administration in Kristiansund also takes care of customer processing, in addition to invoicing for its own department, as well as helping other departments such as Tananger, Mongstad and Sandnessjøen.

|

Drill Cuttings (kaks): is waste material consisting of rock cuttings that are drilled out from boreholes and are contaminated with drilling fluids used in drilling operations. SAR recovers oil from Kaks, which can be reused. Slop: is a mixture of residual drilling fluids, chemicals, wash water, and other liquids generated during drilling. TCC: TCC (Thermomechanical Cuttings Cleaner) is one of the most commonly used thermal desorption techniques for treating drill cuttings. |

Growing range of services - maximum resource utilization

The day starts with a rough plan of activities to be carried out and the planned activities make up about 70% of the working day. The plan is based on fixed agreements and the remaining part of the day is set aside for ad-hoc orders that have come in overnight. Much of the waste comes from the offshore industry, and the size of the deliveries is largely affected by weather conditions. This means that you must be well prepared for hectic activity when the good weather arrives.

A lot has happened at the department in the past six months. In January 2023, SAR took over the activities of the local company Vakumentrepenøren. With that came more equipment, bigger facilities and new employees. This has not only given Kristiansund, but all of SAR, increased resources and wider expertise. With that, we are even better equipped to take care of in-demand services of the market; always with the aim of handling waste according to the best environmentally friendly practices.

The "expansion" was important for SAR's strategy and vision of having the right expertise, equipment and technology to further develop the company. Through maximum resource utilization, such as upcycling, reuse and recycling, waste management becomes sustainable. That's important for both our customers and SAR!

Exciting, complex and demanding tasks

The location continuously receives quantities of slop and cuttings from the offshore industry. In addition to the usual fraction of industrial waste from local businesses and container rental, waste from surrounding industry, construction and other contractor projects is handled. A good and close relationship with the customers is important, and with that comes regular training related to handling, reporting and ordering of services.

Left photo: Daniel Meek, driver and operator, takes water samples on slop water that has been received. An important routine for sorting and for determining further treatment.

Right picture: Well oiled machinery.. Tinus Ingebrigtsen Pettersen is here carrying out maintenance of SAR's machine park.

SAR Kristiansund is also involved in a pilot project of an ordering system developed for a larger customer. Handling several thousand tonnes of waste from the offshore industry is far more complex than ordering containers or collection of ordinary waste. Early planning of treatment capacity and logistics is important to ensure sustainable solutions at every step. It is exciting to be involved in testing new innovative solutions in this field.

Kenneth Romfo Nordbø, operator at hazardous, hard at work.

Waste from methanol production is also sent to SAR Kristiansund. This type of industry offers some slightly more complex and demanding tasks that are exciting to tackle. Some types of hazardous waste produced at such facilities are not transported by boat due to environmental and safety considerations. You then have to be flexible and find good solutions for alternative transport to other facilities.

Barrels of experience..

Barrels of experience..

From the left, Tinus Ingebrigtsen Pettersen and Kenneth Romfo Nordbø standing with barrels that go to customers for waste packaging.

The weather is not like in Hammerfest, but...

Although we are getting further and further south in our journey, we are still along Norway's west coast, and the weather can obviously be a challenge. It is perhaps a bit quieter than what we have seen in Hammerfest and Sandnesjøen, but it still requires good flexibility and careful planning.

From the activity in the Norwegian Sea, supply boats do not leave the quay if the weather is too fierce. Then it is sometimes calmer for the employees, but when the weather clears, a lot more waste has usually built up and arrives at the location simultaneously. Such variations are always taken into account, but require effort and logistics. SAR Averøy, which we will visit next time, is not far away. Here they deal with treatment for SAR's departments and ensure treatment capacity.

The June sun shines on department manager Rune Brattset and customer center manager Anne Lise Varan.

Kristiansund: Opera, offshore, klippfisk

Kristiansund is a relatively small and cozy town, with approx. 25,000 inhabitants. It is spread over 3 islands, and is, among other things, known as the "klippfisk town". Historically, Kristiansund has been Norway's largest producer and exporter of klippfisk, known from the Spanish dish Bacalao. A klippfisk festival is held every year, with a competition to see who can make the best bacalao.

Living city in step with the green transition

The city also has strong roots in music culture. Mainly Opera, classical music and a world-class symphony orchestra. Yes, Kristiansund is both a klippfisk and opera town, with several annual music festivals in the area.

It is rumored that the city’s people has a strong bond, and we are told that if you go out to eat alone and there is life on the table next to you, you may just be invited over.

There is also an exciting versatile business life in the area, where the region has developed strongly in relation to oil refining/chemical and pharmaceutical industries. The offshore industry is central and Kristiansund is an important operations- and supplier-base for the business that takes place at sea in central Norway. This creates both waste and large values that must be handled sustainably.

The value in passing on knowledge

It is not only customers who are offered training. SAR Kristiansund has an open invitation to other institutions, schools and companies who want to learn more about how waste is converted into valuable resources.

"We are always open to people coming to us to see what we are up to here. It could be schools, businesses, or groups that are simply interested in sustainable waste management". - Rune Brattsett, head of the department.

Campus Kristiansund under construction (right), central Kristiansund.

SAR supports students in Kristiansund

Currently, a high-focus investment ongoing is on a large university center under construction in the middle of the city, namely Campus Kristiansund. Here they have a field of study that is directly connected to SAR operations, namely "Sustainable logistics and circular economy". It is always nice to be able to receive students at the location who get to experience how this work is carried out in practice. In addition, it creates good chances for future recruitment of expertise in our field.

SAR – green waste solutions based on cooperation

At SAR, we are proud of the responsibility we have for our customers, the local community, and our partners. We hope that our travel blog has provided some extra insight into our operations at SAR Kristiansund.

New and existing customers are welcome to contact us if you have any questions or wish to use our services.

Together, we will find the best solutions: Greener and Safer!

The previous stop on our journey was Sandnessjøen. Next time, we're heading to Averøy, so sign up for our newsletter to catch our entire journey.